How to chose wood panel products

The panels on the market has a variety of complex naming and selling points, many people still have doubts and misunderstandings. MDF, plywood, particle board, OSB particleboard..... How can I choose from so many?" Today we come to know a few kinds of boards we most often meet.

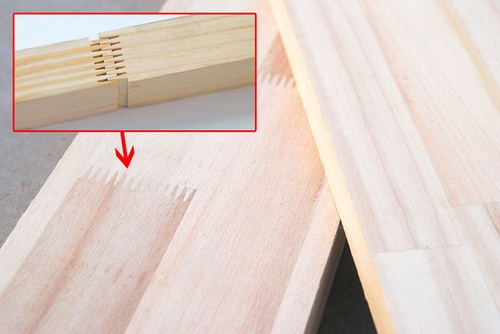

Splice wood board

Splice wood board is made of several boards splicing, up and down no need stick pressure splint, because the vertical board between the serrated interface.

This treatment improves the strength of the wood to some extent, but the physical properties are still very worrying.

Joinery board

On the basis of plywood, a special plywood made of two or more layers of plywood is covered on both sides by splicing or hollow board as core board.

The performance of joinery board mainly depends on core board structure. Its advantages are good grip screw force, high strength, easy to process, but in its production process a large number of adhesive, environmental performance is different; Because its internal material is different, density is different, bending pressure strength is poor, easy to warping deformation, affect the appearance and use effect.

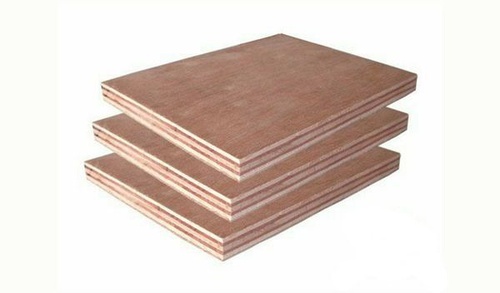

Plywood

Plywood is made up of three or more layers of veneer or sheet wood glue hot pressed together, and then affixed with the veneer, it has become our common custom plate.

The strength of plywood pressed together is greatly improved and the deformation is small; And plywood is good as a result of oneself waterproof, it is the first selection that makes cabinet. However, due to the use of adhesives in the production process, the degree of environmental protection in the selection still needs to be carefully identified.

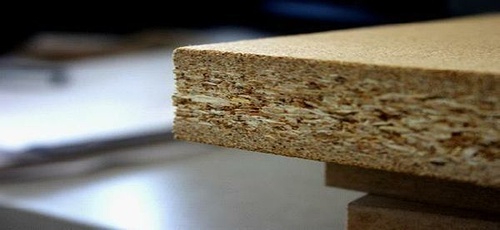

Particle board

Break lumber or wood pole, log, use fine and dense wood fiber on both sides, clip long qualitative wood fiber among, after applying adhesive agent is in heat power and pressure action glue becomes.

Because it is made of wood scraps splicing, so it has smooth and delicate surface and good stability, uniform material, strong nail holding force, not easy to deformation, but easy to expand in case of water.

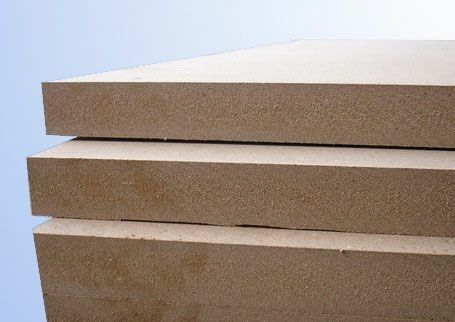

Density board

With wood fiber or other plant fiber as raw material, the application of synthetic resin, under the condition of heating and pressure made.

Density board can be processed into all kinds of modeling door panels because of its uniform structure and fine material. However, the biggest disadvantage of density board is that it has a large expansion rate in case of water, is not moisture-proof, is easy to be deformed and has poor nail holding force.

OSB board

Also known as directional structure particleboard, soft needle, broad-leaved wood small diameter wood, fast thinning wood as raw materials, through drying, sizing, directional paving and hot pressing and other processes.

Its surface layer plane is longitudinal arrangement, the core layer plane is transverse arrangement, this crisscross arrangement recombines the wood texture structure, so that its physical performance is greatly improved, the structure is firm and not easy to deformation, strong nail grip, moisture-proof performance is also better.